Our five nominations turned into one gold, two silver and two bronze medals at POPAI Awards Paris

On Thursday, we succeeded to transmute all of our nominations and won the first place with our Lego Duplo display, the second and the third place in the “Beverages” category with Jaegermeister and Birell realisations and th…

Fresh spring ideas from Pinterest

Inspiration from the world of beverages.

These and many other worldwide POP inspirations can be continually found on

MPV: Adoration of digital technologies had faded also at MPV and analogue realizations “lead the dance”

The Paris Trade Fair did not show many technological innovations. Its creativity consisted primarily in original design and material combinations.

The Marketing Point de Vente (MPV) Trade Fair has traditionally “did” with…

Fascination by technologies has faded and the authenticity “leads the dance” now

From our visit at the Trade Fair Globalshop, it was clear that the digital technologies adoration cooled down.

The Trade Fair Globalshop, which moved back to Chicago this year, radiated noticeably less enthusiasm from digit…

Metaxa is developing the brand in retail

The brand of Greek Metaxa distillates came up with a display in Globus stores. In addition to sales promotion, it focuses on building the brand. This year, there is a good opportunity for it, as Metaxa is just going through…

POPAI Euro Awards Paris – 5 of our projects in the finals

At the Tuesday´s announcement of POPAI Awards Paris, we were the first Czech company with 5 nominations of our projects. There applied 313 projects from 46 categories (last year, 277 realizations in 37 categories). The fina…

BIG SHOCK! Dakar adrenaline

The energy drink brand “BIG SHOCK!” has prepared a competition for its customers to win a ride in a racing special that took part in this year´s Dakar Rally. A two-palette display with a cardboard racing truck special attra…

Remodelling of the Nestlé brand store

Nestlé carried out remodelling of its company store in Prague – Modřany. The assignment sought an innovative solution that will manage to even better represent the company and its products. The combination of materials and…

Adrenaline by OMEN from HP in Alza

A series of game products from HP called OMEN attracts passionate players to a gaming zone in Alza branch stores in Prague and Bratislava. We have created it in a temperament design using geometric shapes and red lighting….

Christmas inspiration from Pinterest

The new software will reduce order processing times by up to three quarters

Production in the P.O.S. segment is very complex and many subjects cooperate within it. For a long time already we have wondered how to manage our individual projects more effectively – from the production itself to the product placement in stores. That is why we started to develop our own software, which will bring all the production attributes together and make it easier to everyone involved in preparations of individual orders – clients, suppliers and our internal teams.

After the development phase, which lasted for one and a half year, we are now testing the new software. And so far, we have been very successful with it. It turns out that a unified project management facilitates work for us as well as for our customers.

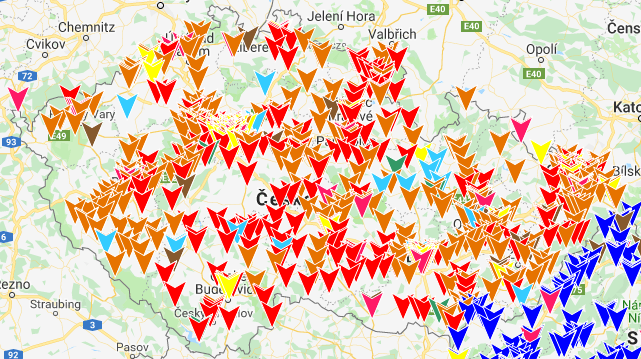

The system constantly transfers all actual data to clients and their business representatives – data about all their displays, where they are located, detailed information about each store, installation plan and so on. If it is found that there is something wrong with any product, they can report the problem using the software and take a photo of its current status using a mobile phone or tablet and upload the image into a cloud.

The time necessary to complete a project rapidly shortens

The system reports the need for ordering appropriate items on time according to warehouse stock and budget and related expenses. It can also accept an order from an information system of a client. So this reduces downtime, which otherwise normally occurs and also the burden of all participating elements because the system automates many activities throughout the implementation process. Stores with installed products are displayed on a map for better clarity; of course it is possible to generate reports and schemes. With regards to data collection in stores, the number and type of monitored P.O.P. media displays in each store is always clear. Thus there is no need for a classic stocktaking, which is now continual. For easier orientation, the products can be filtered according to locality, material, store type, sales representatives and other parameters. Sales representatives and installation technicians have an access to the system available all the time and they can view actual data in certain location using GPS. They should also update information on the spot.

While previously, for example, the placement of three thousand large checkout zones took two or three years, with the new system we can do it in six months. The big advantage is the absolute overview of the installed materials, which enables also repair management and inspection.

10 clients have been participating in the testing and their feedback is very positive. They consider the acceleration of the whole order processing to be the main advantage. Clients have an overview of everything important and approve particular steps just on-line. We see the future in the industry in the closer integration of our comprehensive services with client needs and we are glad that we can already participate in the realization of this vision.

Marek Koncitik and Your DAGO team

SK

SK