Tassimo Floor Displays for Kraft

For the sake of our client Kraft Foods, our company designed, produced and implemented luxury floor displays Tassimo on Czech market in November 2012. These POP stands serve to boost the sale of coffee machines Bosch and co…

Tullamore Dew POP for bars

By seizing the opportunity of introducing new legendary Irish whiskey Tuallamore DEW and in the context of other marketing activities connected with this launch, our company has been addressed by the distributor of this bra…

Popai awards 2012

4 Prize in POPAI Awards 2012. Prague, 26.11.2012 – We have registered seven projects for this year competition in the best POP advertising media in the field of in-store communication POPAI Awards 2012. Three of them have b…

Demo Units Samsung

Samsung Company and its subsidiary agency Cheil (represented by Mr. Kamil Kaliszan) have realized three special demo units for presentation of the newest tablets Galaxy Note 10.1 Samsung in extremely short time due to close…

Wall Display in ElectroWorld

New In-store Solution of Photo Wall in ElectroWorld from Dago Several months have already elapsed when our company has set up cooperation with retail company Electro World s.r.o. in the project on remodelling presentation o…

Chráněné dílny

Naše společnost rozšířila v letošním srpnu spolupráci s organizacemi se statutem chráněná dílna. V kontextu našeho etického kodexu se snažíme pomoci handicapovaným občanům se níženou pracovní schopností, tedy těm, kteří maj…

KOLONÁDA – mobile selling handcart

]

For our client Kraft Foods, we have designed and produced specific presentation unit KOLONADA – a mobile selling handcart in retro style evoking time, when production…

POP Jacobs – promo cups

]

This month, our company has designed, produced and implemented for our client KRAFT FOODS, s.r.o. a set of integrated POP media in order to support consumer promo con…

Huawei POP Demo Unit – Play Table

Huawei Company has decided to cooperate with our Company in order to boost in-store presentation of its products in the demo shop of internet retailer Alza. For this purpose, we have designed, produced and implemented POP a…

Unique palette exposition for Budvar

For our customer Budějovický Budvar, n.p., we have created a non-traditional sales units for secondary exposition of promoted group packages of Budvar beer. In addition to a design and production done in a record time, we h…

The new software will reduce order processing times by up to three quarters

Production in the P.O.S. segment is very complex and many subjects cooperate within it. For a long time already we have wondered how to manage our individual projects more effectively – from the production itself to the product placement in stores. That is why we started to develop our own software, which will bring all the production attributes together and make it easier to everyone involved in preparations of individual orders – clients, suppliers and our internal teams.

After the development phase, which lasted for one and a half year, we are now testing the new software. And so far, we have been very successful with it. It turns out that a unified project management facilitates work for us as well as for our customers.

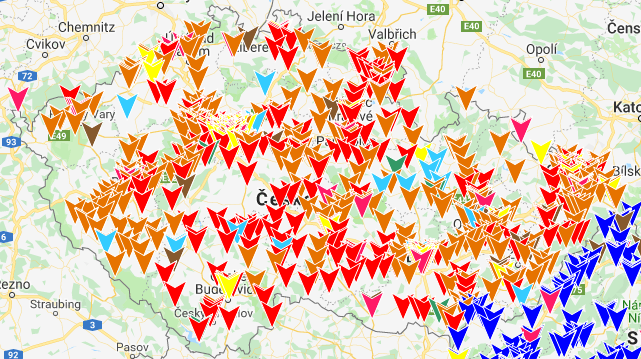

The system constantly transfers all actual data to clients and their business representatives – data about all their displays, where they are located, detailed information about each store, installation plan and so on. If it is found that there is something wrong with any product, they can report the problem using the software and take a photo of its current status using a mobile phone or tablet and upload the image into a cloud.

The time necessary to complete a project rapidly shortens

The system reports the need for ordering appropriate items on time according to warehouse stock and budget and related expenses. It can also accept an order from an information system of a client. So this reduces downtime, which otherwise normally occurs and also the burden of all participating elements because the system automates many activities throughout the implementation process. Stores with installed products are displayed on a map for better clarity; of course it is possible to generate reports and schemes. With regards to data collection in stores, the number and type of monitored P.O.P. media displays in each store is always clear. Thus there is no need for a classic stocktaking, which is now continual. For easier orientation, the products can be filtered according to locality, material, store type, sales representatives and other parameters. Sales representatives and installation technicians have an access to the system available all the time and they can view actual data in certain location using GPS. They should also update information on the spot.

While previously, for example, the placement of three thousand large checkout zones took two or three years, with the new system we can do it in six months. The big advantage is the absolute overview of the installed materials, which enables also repair management and inspection.

10 clients have been participating in the testing and their feedback is very positive. They consider the acceleration of the whole order processing to be the main advantage. Clients have an overview of everything important and approve particular steps just on-line. We see the future in the industry in the closer integration of our comprehensive services with client needs and we are glad that we can already participate in the realization of this vision.

Marek Koncitik and Your DAGO team

SK

SK